Why Choose High Frequency Woodworking Machines? Discover the Key Advantages

2025-07-02 16:24In today’s competitive woodworking industry, efficiency, precision, and sustainability are no longer just goals—they are necessities. High frequency (HF) woodworking machines have quickly become a game-changing technology for both large factories and small workshops. At JYC, we specialize in the design and manufacturing of a full range of high frequency woodworking solutions, including wood board joining machines, vacuum wood dryers, frame assembly machines, wood bending machines, laminating machines, and high frequency generators.

Here are the key advantages of high frequency woodworking machines and why more manufacturers are choosing HF technology for their wood processing needs:

1. Fast Processing and Higher Efficiency

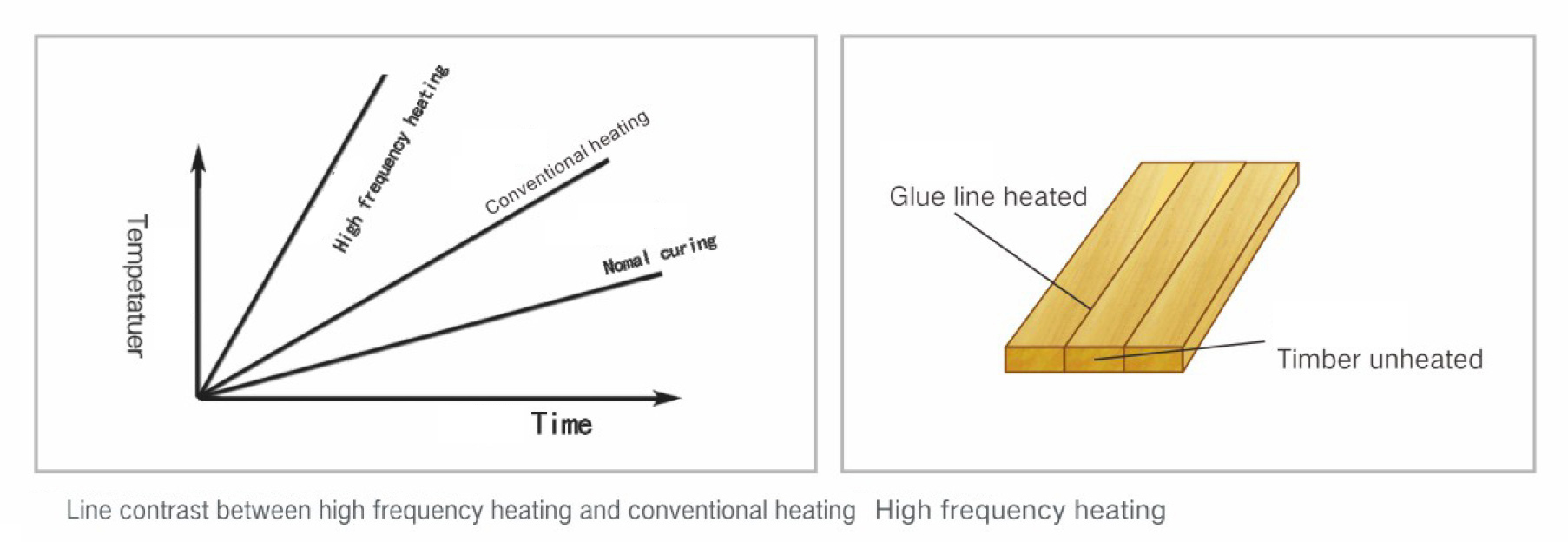

HF technology drastically reduces processing time compared to traditional methods. Whether you are joining panels, bending wood, or drying timber, high frequency machines work faster by using radio frequency waves to heat steam the moisture of materials from the inside out. This internal heating allows for:

Instant glue curing during board joining or laminating

Rapid moisture removal in vacuum drying without surface cracks

Shorter production cycles for bent wood components or assembled frames

2. Energy Saving and Eco-Friendly

Unlike conventional heating or drying systems that require high temperatures for long durations, HF machines use targeted energy, which:

* Minimizes heat loss and power consumption

* Reduces overall carbon footprint

* Promotes cleaner and safer operations

This makes our HF vacuum wood drying machine particularly attractive for companies pursuing sustainable production.

3. Improved Precision and Consistency

High frequency machines offer precise control over pressure, temperature, and timing. This level of control ensures:

* Uniform glue penetration and curing

* Accurate board alignment and seamless joints

* Stable and repeatable results, even with high-value solid wood

Especially in panel joining and frame assembly, precision means fewer rejects and higher product quality.

4. Versatile Applications Across the Workshop

From curved furniture parts to laminated panels and solid wood door frames, JYC's HF machines are designed for multiple applications:

Board Joining Machine – Create wide panels with less manpower

Wood Bending Machine – Shape thick or curved wood quickly

Frame Assembly Machine – Apply pressure in multiple directions

Laminating Machine – Achieve perfect bonding in decorative layers

One HF generator can also power multiple processes, making your production line more flexible and cost-efficient.

5. Safe, Clean, and Operator-Friendly

HF woodworking machines are designed with user safety and workshop cleanliness in mind:

* No open flames or hot surfaces

* Lower working temperatures and reduced emissions

* Cleaner adhesive curing with less odor and waste

At JYC, we also design machines with ergonomic features—like tilting work tables or automatic controls—so operators can work faster and more comfortably.

6. Reliable Technology, Made by Experts

With over a decade of expertise in HF technology, JYC offers not only high-performance machines but also professional technical support and customization services. Our high frequency generators are engineered for long service life and seamless integration across woodworking applications.

Conclusion

High frequency woodworking machines are more than just advanced tools—they are strategic investments in productivity, quality, and sustainability. Whether you run a small furniture workshop or a large-scale production facility, HF technology from JYC can help you improve every step of your wood processing line.