More Productive? You Need This Machine!

2025-06-25 17:101. Core Technology: How HF Bending Works

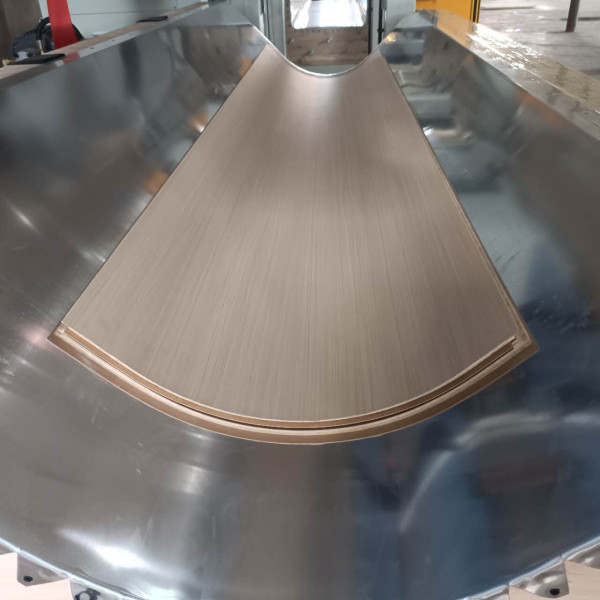

Our machines use 6.78MHz/13.56MHz electromagnetic fields to generate rapid, uniform heat inside wood fibers. This:

- Activates adhesives in 30–180 seconds (vs. hours in cold presses)

- Bends solid wood & plywood up to 35 mm thick without surface scorching

- Delivers ±0.5 mm tolerance curves with zero spring-back

2. Industrial Applications

| Industry | Use Cases |

| Furniture | Chair backs, curved sofas, arched table bases |

| Construction | Stair handrails, arched door frames, dome structures |

| Musical Instruments | Guitar sides, violin ribs, drum shells |

| Sports/Specialty | Ski cores, skateboard decks, artistic sculptures |

3. Key Advantages vs. Traditional Methods

- 90% Faster Production

Glue curing in seconds → 10-30x higher throughput

- Superior Bond Strength

HF wood bending press-activated water-based glue achieves 25% higher shear strength

- Energy Efficiency

No steam boilers → 40% lower operating costs

- Material Versatility

Works with oak, beech, birch ply, bamboo, and adhesive-coated composites

5. Why Manufacturers Choose Our Machines

- Smart Control Systems

Touchscreen PLCs + real-time temp/pressure monitoring

- Multi technical specifications

Multiple models for choice + customized service

- Famous brand electrical components

Brand electrical components are more durable.

Engineering Tomorrow’s Curves Today

Our high frequency wood bending machines transform rigid timber into flawless, durable curves at an industrial scale, merging German-grade precision with operational economy. From mass-produced furniture to bespoke architectural masterpieces, we empower manufacturers to do the impossible with wood.