Wood Frame Clamps vs. HF Wood Frame Assembly Machines – Which is Better for Frame Production?

2025-08-13 16:24In woodworking, assembling strong, precise, and durable wood frames is essential, whether for cabinet doors, drawers, wardrobes, or decorative products. Traditionally, wood frame clamps have been the go-to tool for this task. However, modern manufacturing demands higher speed, accuracy, and labor efficiency, leading to the development of High Frequency (HF) Wood Frame Assembly Machines.

Let’s compare the two methods.

1. Production Speed

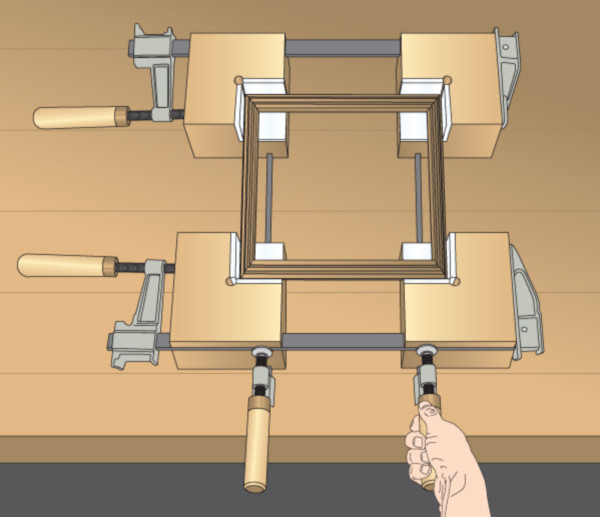

Wood Frame Clamps: Clamping relies on manual tightening and glue curing at room temperature. Depending on the glue, each frame may require 30–60 minutes before unclamping, which slows production.

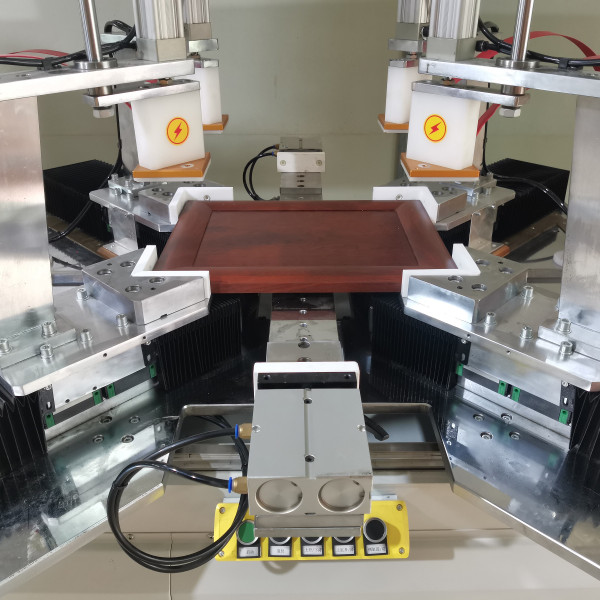

HF Wood Frame Assembly Machines: Using high frequency heating technology, glue cures in tens of seconds. This dramatically shortens cycle time, enabling mass production with minimal waiting.

Winner: HF Machine – Up to 20–30 times faster than manual clamps.

2. Bonding Strength & Quality

Wood Frame Clamps: Bonding depends solely on glue penetration and clamping pressure. Inconsistent manual force may lead to gaps or weak joints.

HF Wood Frame Assembly Machines: High frequency heating ensures the adhesive penetrates deep into wood fibers, while the mechanical pressing system applies uniform pressure to every joint. The result: stronger bonds and higher dimensional accuracy.

Winner: HF Machine – Consistent quality, fewer rejects.

3. Labor Efficiency

Wood Frame Clamps: One worker can only assemble a few frames at a time, and constant supervision is needed to adjust the clamps.

RF Wood Frame Assembly Machines: A single operator can produce frames continuously. Many models even allow materials preparation and HF heating to be done at the same time for greater throughput.

Winner: HF Machine – Less labor, higher output.

4. Versatility

Wood Frame Clamps: Limited to certain frame sizes; changing dimensions means adjusting clamps manually, which takes time.

HF Wood Frame Assembly Machines: Can assemble various frame sizes with quick adjustments. Suitable for furniture, cabinet doors, drawers, and other custom frame products.

Winner: HF Machine – Flexible and adaptable to different products.

5. Cost Efficiency

Wood Frame Clamps: Lower initial investment, but slower speed means higher labor costs over time.

HF Wood Frame Assembly Machines: Higher initial investment, but faster production, reduced labor, less waste, lower overall costs in the long run.

Winner: HF Machine – Better return on investment for medium to large-scale production.

Conclusion

While wood frame clamps are still useful for small workshops or low-volume production, the High Frequency Wood Frame Assembly Machine is the clear choice for manufacturers who want to maximize efficiency, ensure consistent quality, and scale up production.

If your goal is fast, strong, and precise wood frame assembly, upgrading to HF technology is a smart move for long-term growth.