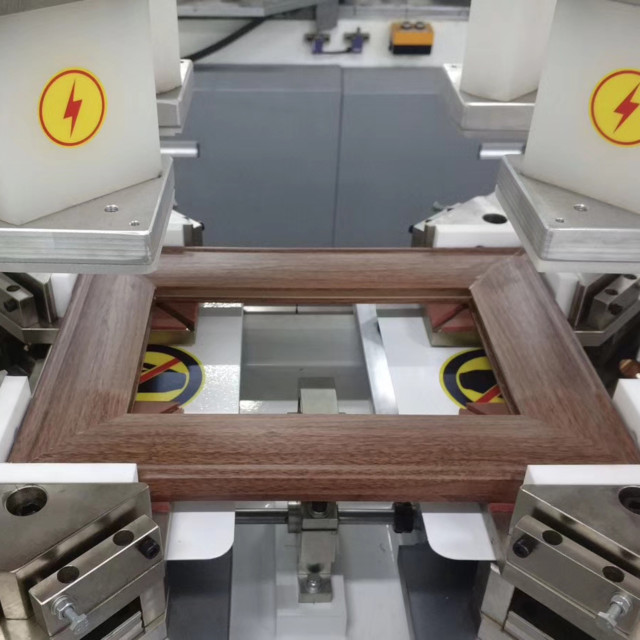

This Machine Can Assembly Wood Photo Frames?

2024-03-04 16:43The assembly of wooden frames is mostly done by manual nailing or manual gluing. Machine assisted assembly can greatly improve efficiency.

High frequency wood frame assembly machines offer several advantages from the perspective of factory production:

Speed and Efficiency: These machines are capable of rapidly assembling wood frames, significantly speeding up the production process compared to manual assembly or traditional machinery. The high frequency technology enables quick bonding of wood components, reducing production time per unit.

Consistency and Precision: Automated assembly ensures consistency in product quality and precision in measurements. Each frame produced by the machine is identical, leading to fewer defects and rework. This consistency is crucial for meeting quality standards and customer expectations.

Labor Savings: By automating the assembly process, high frequency wood frame assembly machines reduce the need for manual labor. This not only lowers production costs but also frees up labor for other tasks within the factory, such as quality control, maintenance, or innovation.

Reduced Waste: Automated machines are highly precise in their operations, minimizing material wastage during assembly. This contributes to cost savings and aligns with sustainability goals by reducing the environmental impact associated with wood waste.

Flexibility and Customization: Many radio frequency wood frame assembly machines can be programmed to accommodate various wood sizes and shapes, allowing for greater flexibility in production. This capability enables factories to fulfill custom orders efficiently and adapt to changing market demands.

Improved Safety: Automated assembly reduces the risk of workplace accidents associated with manual handling of heavy wood components and operating traditional machinery. By minimizing human involvement in potentially hazardous tasks, these machines contribute to a safer work environment.

Data Monitoring and Analysis: Advanced HF wood frame assembly machines often come equipped with sensors and monitoring systems that collect data during the production process. This data can be analyzed to identify areas for optimization, improve efficiency, and predict maintenance needs, ultimately enhancing overall factory performance.

Competitive Advantage: Investing in modern, automated machinery like RF wood frame assembly machines can give factories a competitive edge in the market. Efficient production processes translate to shorter lead times, competitive pricing, and the ability to take on a higher volume of orders, thus attracting more customers and driving business growth.

Overall, high frequency wood frame assembly machines offer numerous advantages that contribute to increased productivity, cost savings, product quality, and competitiveness for woodworking factories. Check out the video! You can feel the efficiency brought by the HF wood frame assembly machine more intuitively!