Looking for a Faster and Easier Way to Assemble Wooden Frames?

2025-10-29 15:31In modern woodworking production, efficiency and precision are key. The High Frequency Slant Worktable Wood Frame Assembly Machine is designed to meet both — combining ergonomic design with advanced high frequency technology for superior frame assembly results.

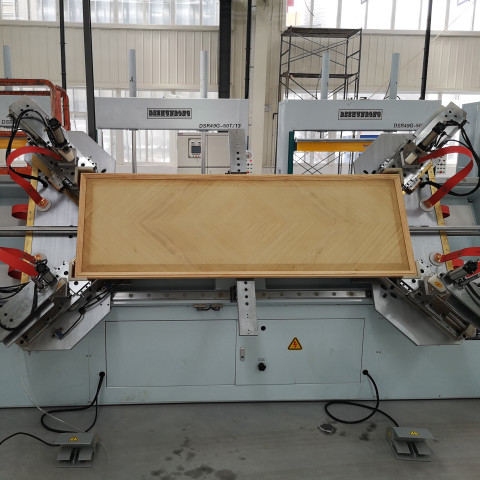

The machine’s slant worktable design makes operation easier and more comfortable. Operators can pick and place workpieces effortlessly, reducing labor intensity while improving assembly accuracy and speed. This thoughtful design not only enhances efficiency but also ensures consistent quality during continuous production.

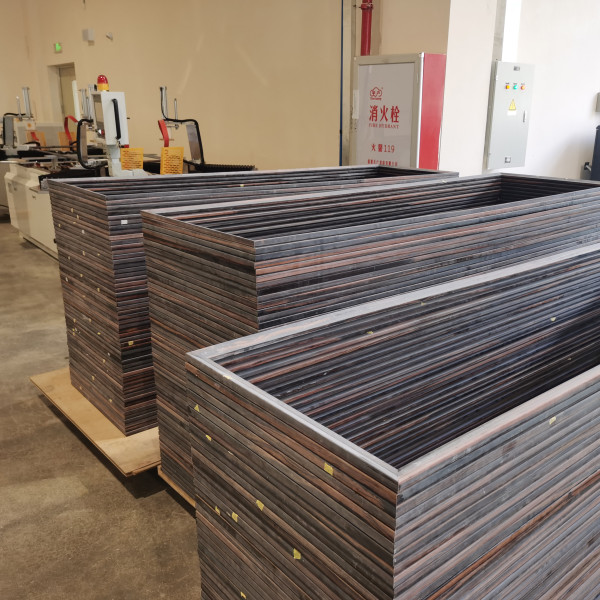

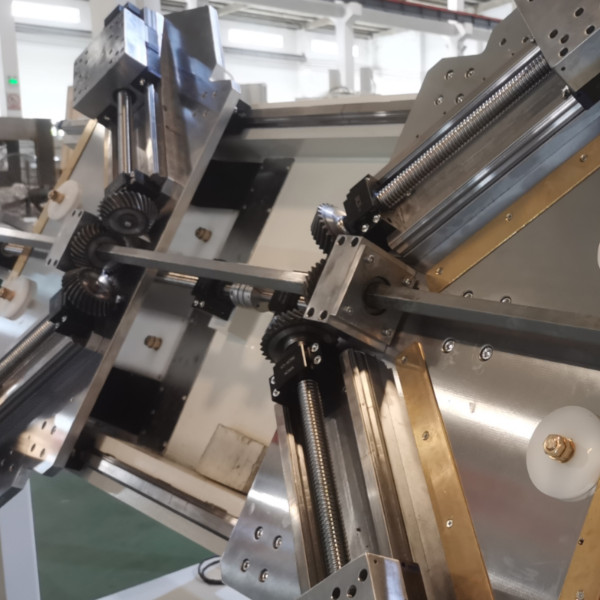

Equipped with high frequency heating, the machine provides fast, uniform, and highly accurate gluing across connection points. This ensures strong, gap-free joints even for large wooden frames. It’s ideal for assembling photo frames, wooden door frames, window frames, and other large or complex structures that require perfect alignment and durability.

This machine can assemble wooden frames within a customizable size range, allowing users to handle different frame dimensions with ease. Both the maximum and minimum assembly sizes can be tailored to customer requirements, ensuring flexible and precise positioning for every production need.

Compared with traditional assembly methods, the high frequency system offers:

Instant curing — no need to wait for glue to dry

Precise positioning — accurate angle control for flawless corners

Labor-saving design — easy loading and unloading

Stable performance — consistent results batch after batch

With the HF Slant Worktable Frame Assembly Machine, frame manufacturers can achieve higher productivity, stronger joints, and a more comfortable working environment — all at once.

JYC continues to bring innovation and reliability to the woodworking industry, helping customers worldwide improve both quality and efficiency.