- Home

- >

News

In the world of woodworking, bending wood is an art form. It allows for the creation of beautiful, flowing curves that add character and dimension to furniture, architectural elements, and a wide range of other wood products.

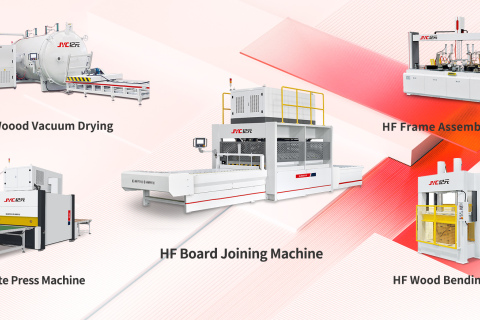

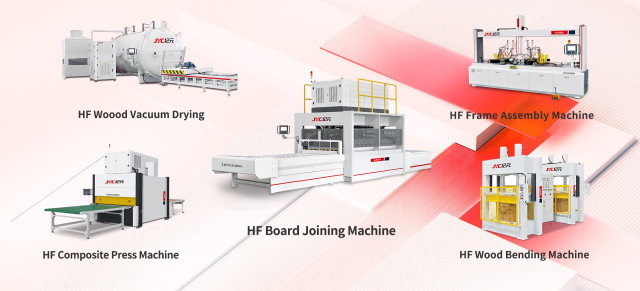

High frequency generators are revolutionizing woodworking by enhancing efficiency and precision in processes like drying, joining, bending, and laminating.

This article delves into the diverse applications of bent wood in furniture and introduces the high frequency wood bending machine—a revolutionary tool in modern woodcraft.

Plywood chairs, known for their strength, durability, and aesthetic appeal, often require complex bending and shaping to achieve their final form.

In the realm of modern woodworking technology, the high frequency curved wood press machine stands out as a versatile and essential tool.

Solid wood material preparation is an extremely important front-end task in home furnishing manufacturing production.

In furniture manufacturing, the front-end solid wood preparation primarily encompasses key processes such as drying, cutting (finger jointing), and panel assembly, directly impacting raw material utilization, subsequent processing efficiency, and the final product quality. However, amidst the current trend of automation upgrades, solid wood preparation still faces numerous challenges in efficiency and quality.

2024 China International Furniture Fair (TianJin)

If You Produce Curved Wood, High Frequency Wood Bending Machine IS Your Best choice!!!

JYC has focused on high frequency technology for more than 30 years.