- Home

- >

News

Getting wood to the ideal moisture content for optimal performance and longevity has always been a delicate balance between speed, quality, and resource consumption.

We cordially invite you to visit our booth to explore our latest machinery and innovations.

Wood drying is a critical process in woodworking, influencing its quality and durability.

Solid wood laminated is a type of artificial wood material formed by bonding multiple layers of thin wood veneers through specific processes.

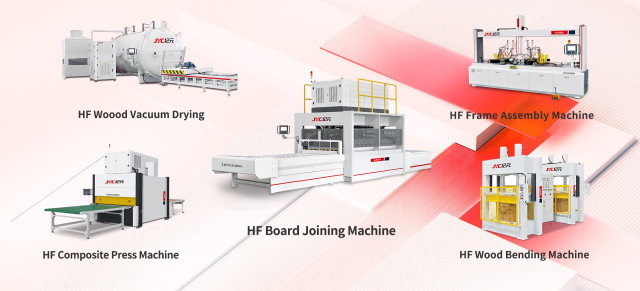

In furniture manufacturing, the front-end solid wood preparation primarily encompasses key processes such as drying, cutting (finger jointing), and panel assembly, directly impacting raw material utilization, subsequent processing efficiency, and the final product quality. However, amidst the current trend of automation upgrades, solid wood preparation still faces numerous challenges in efficiency and quality.

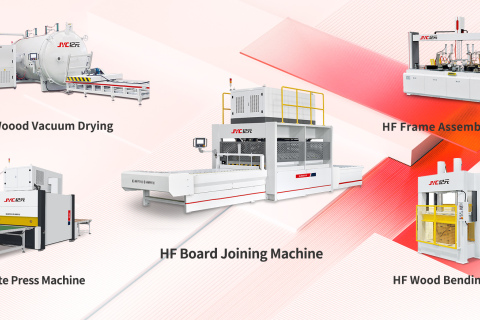

2024 China International Furniture Fair (TianJin)

Unlike microwave or air drying, high frequency heating technology dries the wood from the inside to the outside.

JYC has focused on high frequency technology for more than 30 years.

As we know, there’s a long history of wood application in homes and offices.

A good environment can make manufacturing better!