Why Choose High Frequency Vacuum Wood Drying? Discover the Key Benefits

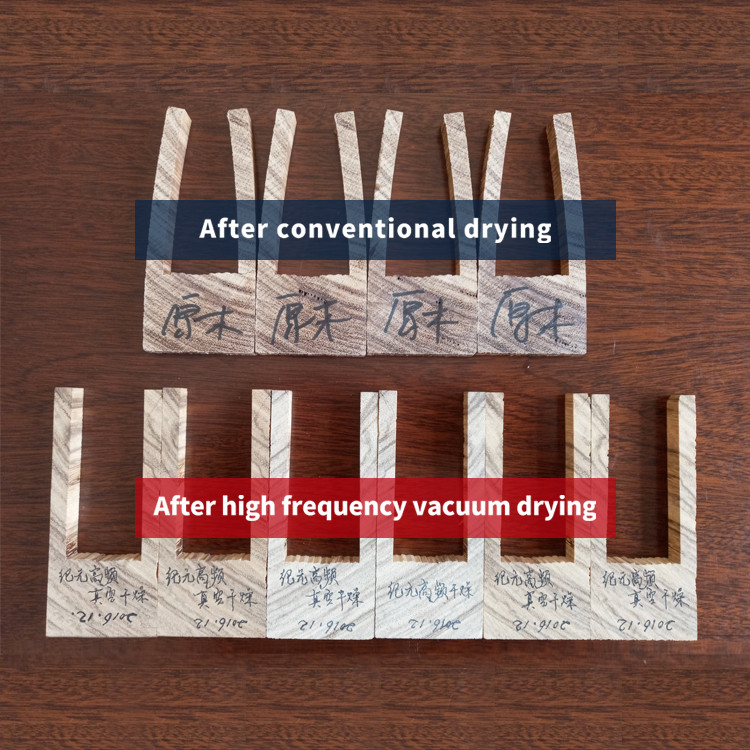

2025-07-23 15:48In the woodworking and furniture manufacturing industry, drying wood efficiently and effectively is crucial for ensuring product quality, preventing defects, and speeding up production. Traditional kiln drying methods are often slow, uneven, and can lead to internal stress, cracking, or warping. This is where High Frequency Vacuum Wood Drying Machines (HF vacuum wood dryers) make a big difference.

At JYC, we specialize in high frequency woodworking technology, and we’ve seen how HF vacuum drying can revolutionize wood processing. Here's why more and more professionals are choosing this advanced drying solution:

1. Fast Drying Time – Up to 10x Faster than Traditional Kilns

High frequency vacuum drying equipment uses electromagnetic waves to heat the wood from the inside out. Unlike traditional surface heating, this method rapidly removes moisture throughout the entire thickness of the wood. For thick, dense wood or hardwood species, drying time can be reduced by up to 80–90%, helping you meet tight production schedules with ease.

2. Uniform Drying – No Surface Cracks or Internal Stress

Traditional kilns often dry the outer layer first, causing cracks or case hardening. HF vacuum drying ensures even moisture removal by heating all parts of the wood equally. This helps maintain the wood's structural integrity, minimizes warping, and avoids the defects that often result in waste or rework.

Traditional K iln Drying

3. Low Temperature Drying – Ideal for High-Value Wood

Because the process takes place in a vacuum, water inside the wood boils at a much lower temperature (as low as 90°C). This protects the wood from overheating, burning, or color degradation—making HF vacuum drying perfect for valuable species.

4. Energy Efficient and Environmentally Friendly

HF vacuum wood dryers are highly energy-efficient. Since the energy directly targets moisture in the wood, there's little heat loss. Plus, the vacuum system reduces the need for external heating, saving both electricity and operating costs. It also produces less CO₂ and emissions compared to traditional wood kilns.

5. Compact Machine Size – Save Space in Your Workshop

Unlike large-scale kiln setups, JYC’s HF vacuum wood dryers are compact and space-saving, making them ideal for small factories, woodworking studios, or workshops with limited space. Despite their size, they offer industrial-grade performance and flexibility for a wide range of wood types and dimensions.

6. Smart Control System – Easy to Operate

Modern RF vacuum wood drying machines come with intelligent control panels that monitor and adjust drying parameters automatically. Even without deep technical knowledge, operators can manage the drying process easily, ensuring consistent and high-quality results every time.

7. Customizable to Different Wood Types

Whether you're drying oak, walnut, pine, acacia, rubberwood, or engineered panels, JYC offers customizable HF vacuum drying systems to suit your specific needs. Our machines can be tailored to different wood sizes, thicknesses, and moisture content requirements.

Conclusion: Upgrade to the Future of Wood Drying

For manufacturers, carpenters, and woodworking studios that care about efficiency, quality, and sustainability, High Frequency Vacuum Wood Drying Machines offer unmatched advantages. With faster drying times, better quality results, and reduced energy costs, it's a smart investment that pays off in the long run.