From Photo Frames to Wine Boxes: Discover JYC' s High Frequency Frame Assembly Solutions

2025-07-16 16:54In today’s competitive woodworking industry, versatility and precision are paramount. Whether you’re crafting delicate photo frames or large-scale wardrobe panels, the right assembly machine can make all the difference. JYC proudly offers a comprehensive range of high frequency (HF) frame assembly machines, each engineered to streamline production, ensure consistent bond quality, and adapt seamlessly to diverse wooden frame products—photo frames, cabinet doors, drawers, closets, cabinets, wine boxes, wardrobes, and beyond.

1. Precision Photo Frame Assembly

Compact footprint for tabletop or benchtop setups

Adjustable pressure settings to protect delicate moldings

Quick-change fixtures accommodate multiple profile widths in minutes

Ideal for boutique studios and photo‑frame manufacturers seeking high-quality, low‑volume runs without sacrificing efficiency.

2. Cabinet Door Joining

Wide working area up to 1.5 × 2 m for full‑size doors

Variable frequency control for different substrates (MDF, solid wood, composites)

Integrated glue feed system for consistent adhesive application

Perfect for cabinet shops requiring fast cycle times and flawless edge‑to‑edge bonding.

3. Drawer Box Construction

Precision corner alignment with laser‑guided positioning

Multi‑station fixtures allow simultaneous bonding of multiple drawers

User‑friendly HMI with pre‑programmed recipes for different drawer styles

Engineered to bolster throughput in furniture factories, delivering square, durable drawer boxes every time.

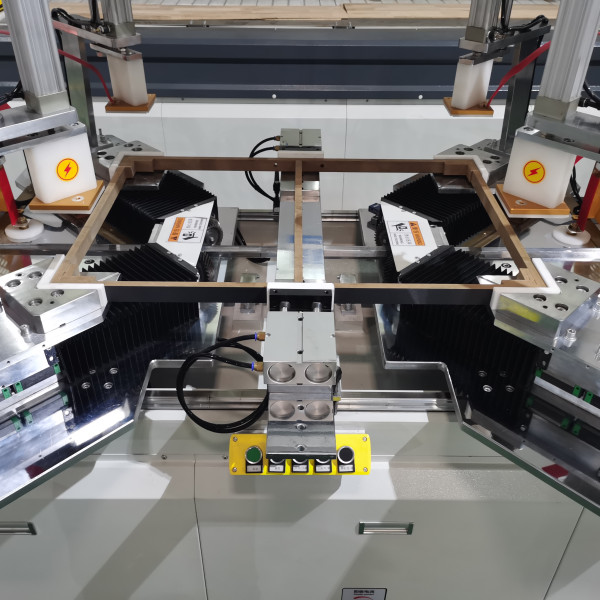

4. Closets & Cabinet Frames

Heavy‑duty frame supports large, weighty assemblies

Customizable platen sizes to match bespoke cabinetry dimensions

Safety light curtains ensure operator protection during automated cycles

A must‑have for manufacturers of modular and walk‑in closets, wardrobes, and custom cabinetry.

5. Wine Box & Gift Case Assembly

Delicate fixture inserts for thin-profile walls and sliding lids

Programmable dwell time to accommodate specialty glues and finishes

Low‑pressure modes prevent deformation of fine‑grain woods

Ideal for luxury packaging producers and gift‑box artisans looking to elevate product presentation.

Key Advantages of JYC HF Frame Assembly Machines

Rapid Heating : RF heat minimizes production time.

Uniform Bonding: Consistent energy distribution ensures gap-free joints.

Energy Efficiency: Targeted RF heating reduces overall power consumption.

User‑Friendly Interface: Intuitive touchscreens and programmable recipes.

Modular Design: Easily upgrade or reconfigure fixtures as your product mix evolves.

From intricately detailed photo frames to robust wardrobe panels, JYC’s versatile HF frame assembly lineup has you covered. Engineered for precision, speed, and adaptability, our machines empower woodworking professionals to expand their product offerings without compromising quality. Ready to elevate your production? Contact JYC today to find the perfect HF assembly solution for your wooden frame projects.